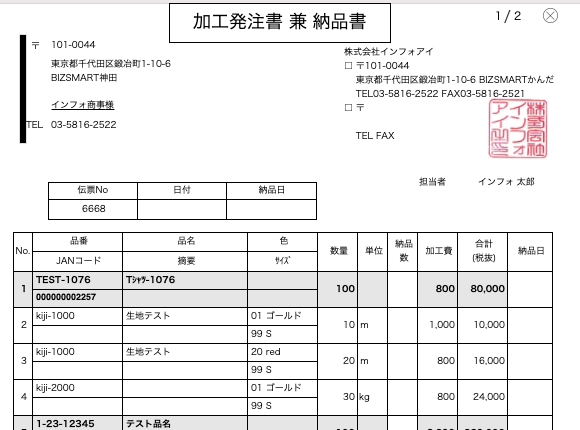

We added functions for processing orders, apportionment processing, and actual apportionment processing to APASYS.

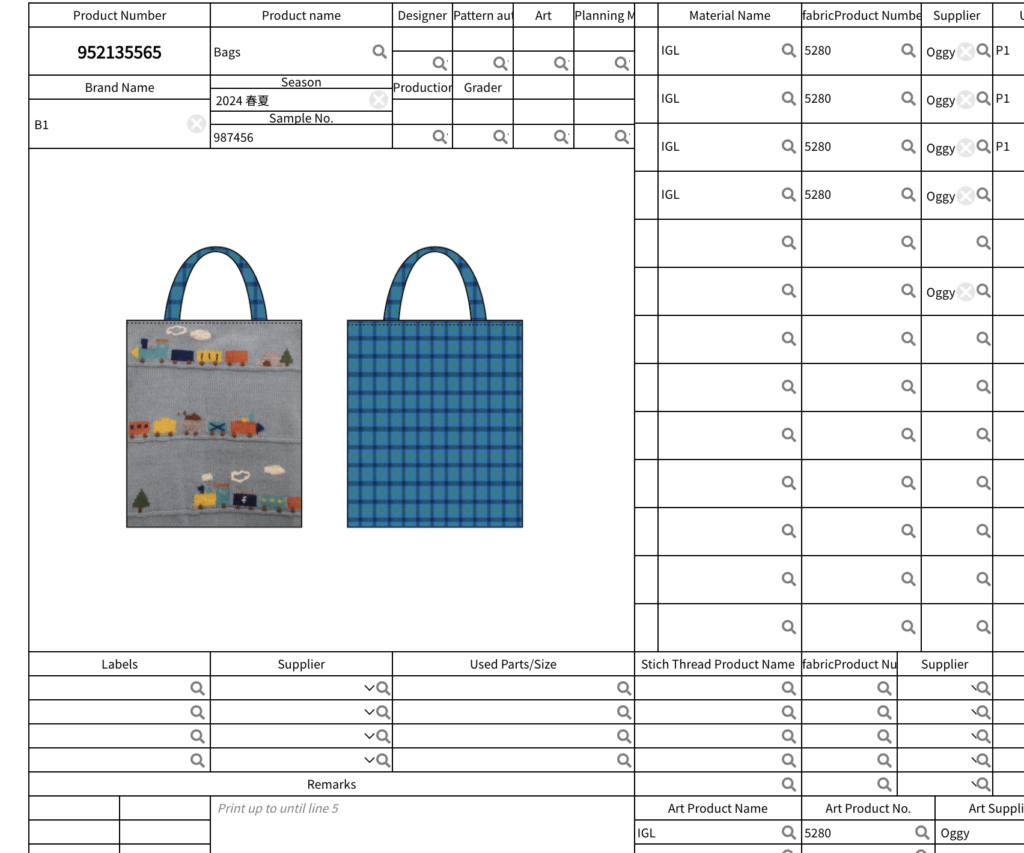

To make one product, we send the gray fabric and materials to a processing shop, and the finished product comes out as a single product, or only the embroidery is done.

Up until now, there has been a function similar to the processing order function, but I think the release of this function has made it feel more refreshing.

Naturally, when moving gray fabrics etc. during processing orders, inventory must be reduced, and various units of shipping should also be considered.

Of course, when the product is returned, the units have changed.

Also, they may be produced by groups.

We were able to release this series of steps as a feature of APASYS while discussing with the customer (๑>◡<๑).